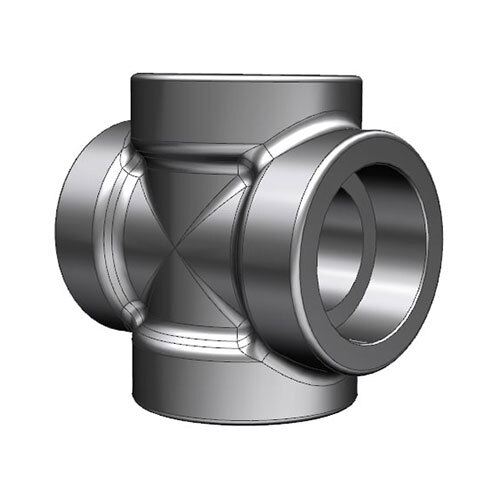

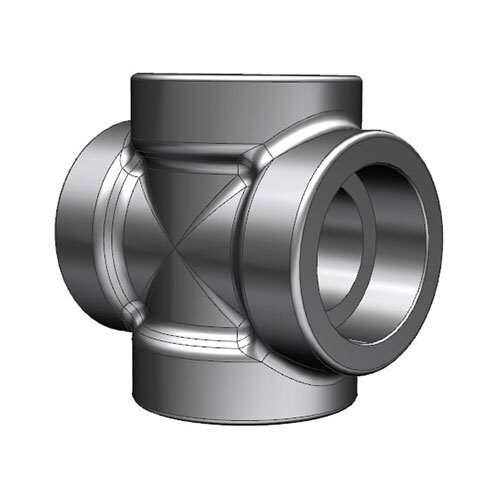

F 60 - Stainless Steel Forged Fittings

Product Details:

- Material Stainless Steel

- Usage Industrial

- Surface Finish Polished

- Type Seamless

- Technics Hot Rolled

- Standard ASME

- Size 1/8" to 4"

- Click to View more

X

F 60 - Stainless Steel Forged Fittings Price And Quantity

- 100 Piece

F 60 - Stainless Steel Forged Fittings Product Specifications

- Polished

- 1/8" to 4"

- Industrial

- F 60

- Seamless

- ASME

- Stainless Steel

- Hot Rolled

F 60 - Stainless Steel Forged Fittings Trade Information

- 5000 Piece Per Month

- 7 Days

Product Description

The F 60 Stainless Steel Forged Fittings are seamless fittings made from high-quality stainless steel material. These fittings are manufactured using hot rolled technics and meet the ASME standard, making them ideal for industrial use. The surface finish is polished, giving them a sleek and professional look. These fittings are available in sizes ranging from 1/8" to 4" and are of Grade F 60, ensuring durability and strength for various industrial applications.

FAQs of F 60 - Stainless Steel Forged Fittings:

Q: What material are the F 60 Stainless Steel Forged Fittings made of?

A: The F 60 Stainless Steel Forged Fittings are made of high-quality stainless steel material.Q: What is the standard followed for these fittings?

A: These fittings meet the ASME standard.Q: What sizes are available for these fittings?

A: These fittings are available in sizes ranging from 1/8" to 4".Q: What is the grade of these fittings?

A: The F 60 Stainless Steel Forged Fittings are of Grade F 60, ensuring durability and strength.Q: What is the surface finish of these fittings?

A: The surface finish of these fittings is polished, giving them a sleek and professional look.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Contact Us

Contact Us Send Inquiry

Send Inquiry Send SMS

Send SMS